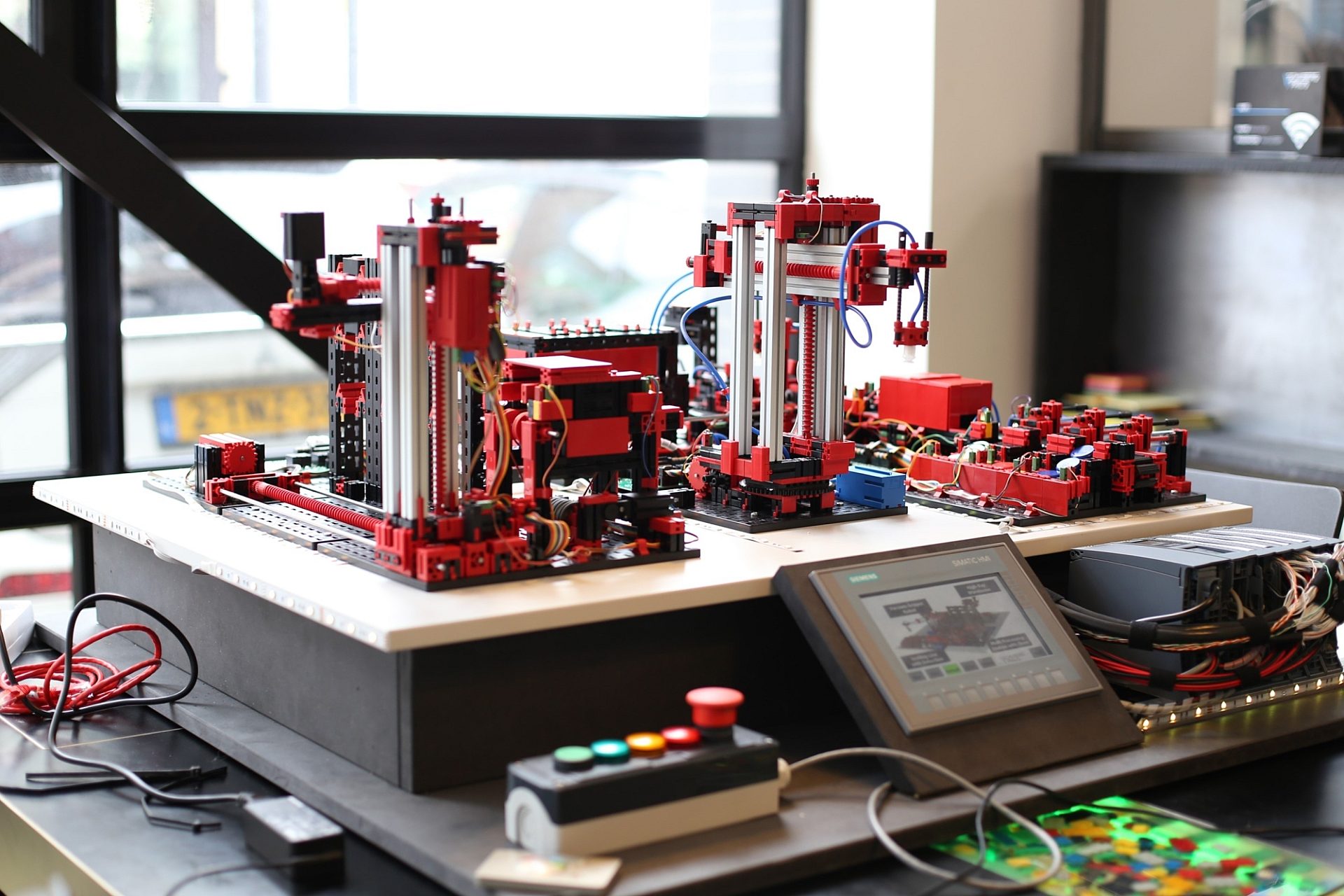

To illustrate what they mean, Kuipers and Heitlager show off a small-scale, working model of an intelligent factory that simulates a beer brewery. The real plant’s supply chain is incredibly complex, involving multiple partners whose data systems are not mutually compatible or standardized. But through the model factory in Lab271, Schuberg Philis succeeded in finding a novel way to incorporate all the relevant information into a single, unified whole.

Ilja Heitlager: “Even though these are in fact major assets, what you actually see here in a small-scale model is the representation of Industry 4.0. Individual production lines are digitized and brought together so that, based on data and intelligence, the entire system can be controlled in the best way in real time. This is how we bridge the gap between physical engineering and IT.”

Roeland Kuipers: “Once you have the right data points, not only can you follow one specific production line and improve the performance of each machine—you can also centralize all the lines and manage them as a whole. Thanks to our experience with this small-scale model, we were able to get things up and running in a real production line within a single day. Practicing first gave us a great head start once it came to the real thing.”

Experts in the lead

According to both the CTO and the CIO of Schuberg Philis, business-oriented innovation demonstrates new forms of interaction with the partners the company is serving. Long-term relationships based on a tender, for instance, as well as planning and major contracts are making way for more experimental interactions with short to very short cycles. The added value for the business always comes first. Then, after a proof of concept or a minimum viable product has been created, things can be scaled up rather quickly.

Ilja Heitlager: “Here at Schuberg Philis, we are adding something very important: a focus within a mission-critical cloud infrastructure on security, including data security, and continuity. Systems that make it possible to run an industrial environment intelligently are not necessarily secure. For example, a secure connection to an IT infrastructure requires additional measures.”

Roeland Kuipers: “Here, too, we are starting from two principles that are quite important for Schuberg Philis: ‘experts in the lead’ and ‘the whole system in the room.’ Our customer contributes specific knowledge of its business, processes and IT, while we deliver competencies in technical and data engineering and science. And we team up with specialized partners when needed. Instead of thinking up everything individually, we go on a joint hunt for value.”